Audi thermal management put to the test

missing translation: fa.article-intro.reading-time – 04/06/2022

missing translation: fa.article-intro.reading-time – 04/06/2022

Mr. Kröner, what does the thermal management of an Audi e-tron have to do?

In order to deliver an adequate performance even at more extreme temperatures, the vehicle’s high-voltage battery must, for example, be warmed or cooled. Thermal management ensures that this can work as well as possible in its ‘comfort range’.

This is like the performance of a smartphone battery which can be more limited at low temperatures than in the normal temperature range.

Thermal management makes a significant contribution when it comes to preventing temperature-related drops in the performance of the HV battery and other HV components. In everyday operation, short-term deviations from the comfortable temperature generally have little effect on system performance.

But the thermal management system isn’t comparable to, for example, the thermostat on a radiator?

Absolutely not. The thermal management of an Audi e-tron uses several coolant and refrigerant circuits. They are activated as required to cool or heat the interior, powertrain or battery. There are more than 200 interconnection options that must be used so intelligently that we achieve the desired temperature control in each case.

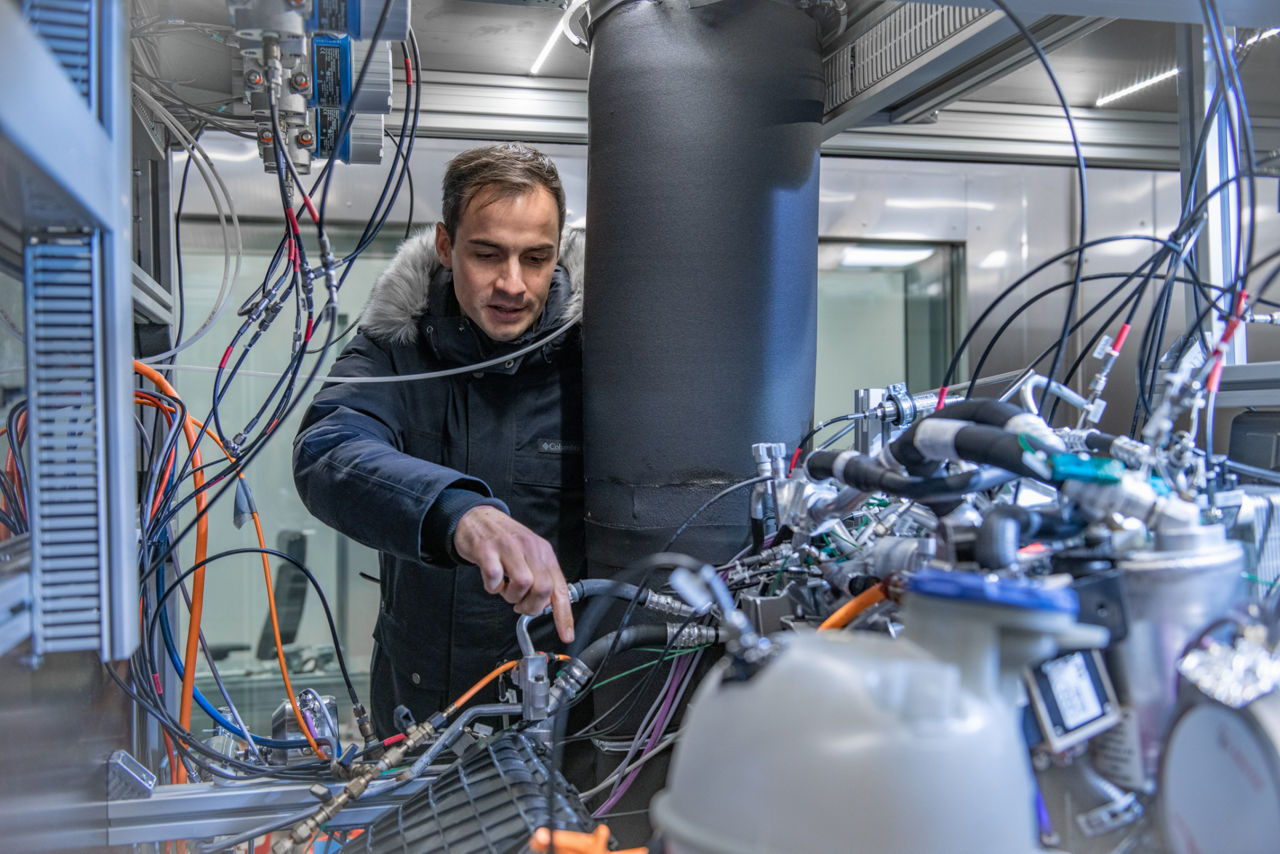

Christoph Kröner during a routine check of the thermal management system and the connected measurement technology at -10°C.

How do you determine whether the interconnections are working as desired?

Relevant tests on real vehicles are highly complex, expensive and time-consuming. That’s why here in Gaimersheim, together with our colleagues within Audi, we have developed a new testing bay, unique in the VW Group, that can present our test scenarios at a very early stage, regardless of the vehicle. This testing bay has been operational since 2020 and can realistically simulate virtually all driving conditions, significantly simplifying our work. With it we can recreate a wide variety of test scenarios that thermal management must cope with in order to validate the thermal management functions. The number of variations that we process with it is enormous. We are currently testing possible future configurations on the basis of around 120 project variants with an average of 100 test cases each. That’s why we also use the power of at least a dozen high-performance computers to carry out our measurements. It means we learn in real time whether our thermal management software works with the coolant and refrigerant circuits as designed or whether we need to optimize.

But this vehicle is virtual?

Not entirely. Everything that is important for thermal management, such as the control unit, coolant and refrigerant circuits as well as, for example, the air inlets of the air-conditioning system, are actually used in the correct position in a so-called ‘test trolley’. The real assembled parts therefore replace the real vehicle. We also create the necessary outside temperature, humidity or airflow on site. But we use the data from real routes to simulate the respective driving conditions. Yesterday morning, for example, we tested individual settings on the drive through Death Valley National Park and, in the afternoon, we took a virtual drive around the Nürburgring.

So, you use real values that were obtained in advance during drives at the corresponding locations to carry out virtual test runs on the behavior of the thermal management system?

That’s right. These are measured values for the drive itself, i.e., on the gradient, the curve radii, the average cornering speed on the racing line, possible accelerations and braking processes. We combine this information with our data on the microclimate locally as well as individual requirements for the air-conditioning system, for example, and for different loads.

In the testing bay’s control center in Gaimersheim, Christoph Kröner tests the thermal management under generated extreme conditions.

Components that are not actually built in the testing bay are represented as an external heat source. Christoph Kröner checks the heat exchanger of the simulated high-voltage battery and the electric powertrain during a test at -10°C.

In the testing bay’s control center in Gaimersheim, Christoph Kröner tests the thermal management under generated extreme conditions.

Components that are not actually built in the testing bay are represented as an external heat source. Christoph Kröner checks the heat exchanger of the simulated high-voltage battery and the electric powertrain during a test at -10°C.

So, for example, you can test thermal management in Death Valley?

In California’s Death Valley we set off virtually with a fully loaded trailer at an outside temperature of 50°C; the air is extremely dry. After that the situation changes, because our virtual vehicle travels at, for example, 60 km/h (37 mph) and can use the airflow for cooling. Then again, it must repeatedly overcome gradients of up to nine per cent. We calculate the temperature development in the vehicle and can analyze how well the different coolant and climate-control circuits and the control unit software are working in order to produce the requisite temperature for component cooling and for the interior.

Are tests in cold regions run in a similar way?

Yes. One of my personal favorite routes that we use for these tests is the Grossglockner High Alpine Road in Austria. In winter here snow up to 10 meters deep and icy temperatures are the norm. Our drive over the Bernina Pass in Switzerland also offers very dynamic temperatures. In total, we currently use 50 different tours with their specific characteristics to test thermal management. At the same time, we can also simulate unusual situations, such as the effects of an outside temperature of -20°C during a fast lap at the Nürburgring.

Air gap for simulating the airflow for an Audi e-tron. Airflows of over 300 km/h (186 mph) can be represented here in different temperature ranges.

An Audi e-tron testing trolley with all the relevant components for thermal management. The trolley replaces the real vehicle.

Air gap for simulating the airflow for an Audi e-tron. Airflows of over 300 km/h (186 mph) can be represented here in different temperature ranges.

An Audi e-tron testing trolley with all the relevant components for thermal management. The trolley replaces the real vehicle.

And all these test drives run automatically?

Obviously, we have to make the relevant preparations. After that however, thanks to sophisticated automation, the required test cases run through autonomously – day and night and, if necessary, also seven days a week.

Then Audi doesn’t need to carry out any more actual test drives – at least relating to thermal management?

There will continue to be real test drives, but as a result of our work it’s possible to test driving scenarios at a very early stage of the project when there are no finished vehicles yet. Later, we then also support the actual vehicle testing in the testing bay as measurements can be carried out more easily and quickly here.