Audi strives to achieve optimal resource savings along the entire value chain and to embed the principle of the circular economy more firmly into the development, production and use of its vehicles. High-quality products that require the least possible repair are aimed at ensuring the longevity of Audi models in their utilization phase and therefore contribute significantly to resource efficiency. Should a part nonetheless need to be exchanged, Audi offers three different exchange options for selected parts:

Brand new parts can be sourced by customers as Audi Genuine parts.

Audi Genuine used parts, on the other hand, are parts that are used but functional and can be resold without remanufacturing.

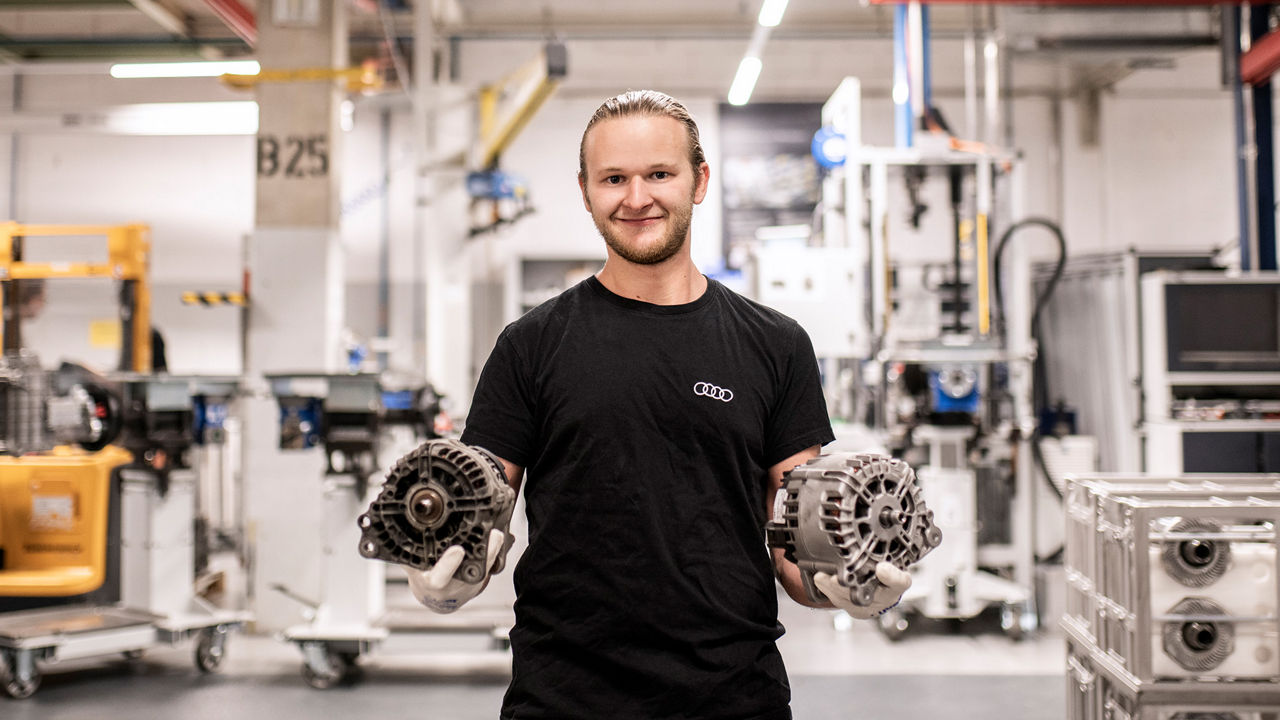

Audi Genuine exchange parts, in turn, are formerly non-functional, remanufactured Audi Genuine parts. Customers are only given these remanufactured vehicle parts in exchange for a defective part. Ideally, a defective part is exchanged for a remanufactured part. If, for whatever reason, used parts cannot be remanufactured directly within the Audi Genuine exchange parts program, they are replaced by new parts (Audi Genuine parts).

.jpg)