Sustainable right down to the very last detail

To become the leading carbon-neutral premium provider, Audi is optimizing all parts of its value chain. An overview of key improvements and initiatives.

missing translation: fa.article-intro.reading-time – 01/16/2024

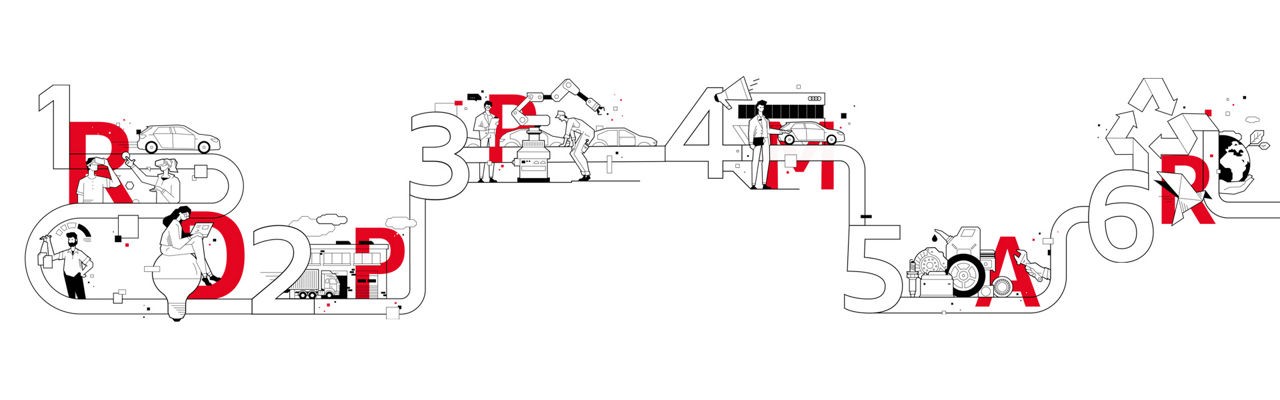

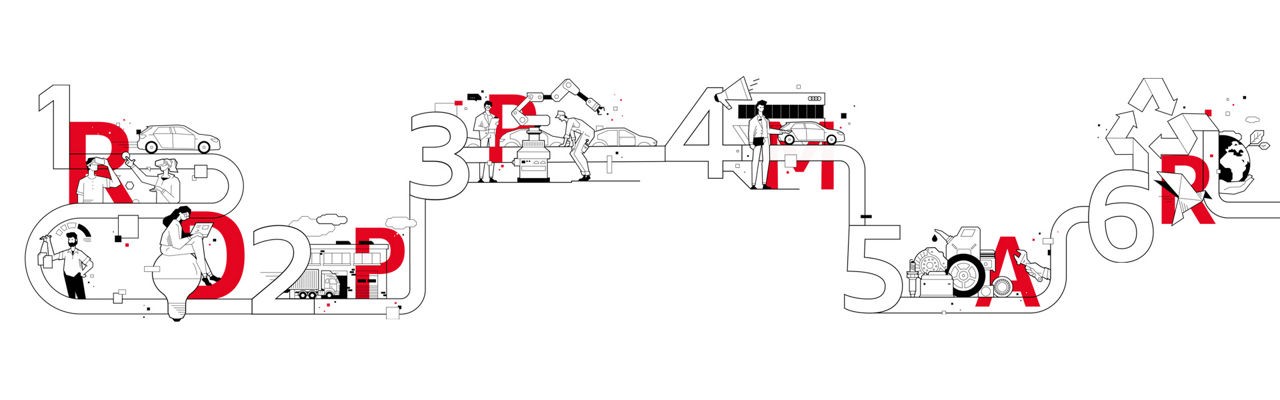

Infographic of the automotive value chain: The letters RD stand for research & development, the first P for procurement, the second P for production, the M for marketing, the A for after sales and the R stands for Recycling.

Infographic of the automotive value chain: The letters RD stand for research & development, the first P for procurement, the second P for production, the M for marketing, the A for after sales and the R stands for Recycling.

Research & development

Audi is embarking on a great transformation. The company aims to reduce its carbon footprint by around 30 percent in just five years. Audi wants to be carbon-neutral by 2050. Rigorous electrification of vehicle fleets contributes to promoting decarbonization.

Research and Development Department is currently working intensely on introducing around 30 electrified models to the market by 2025; they are intended to make up approximately 40 percent of the brand’s sales.

Furthermore, Audi is banking on plug-in hybrids and, in the future, on the h-tron fuel cell drive system. Research and development activities pertaining to fuel cells are being conducted at the competence center in Neckarsulm, which has assumed the lead within the Volkswagen Group.

Thanks to the mild-hybrid systems, vehicles with combustion engines also emit less CO₂ than they did in the past. Once the driver takes his or her foot off the gas pedal, the drive management system selects from one of two options: Depending on the driving situation and the setting in the “Audi drive select,” the vehicle either recovers energy or it glides with the engine switched off.

The vision is to shape premium mobility in a manner that is both effortless and sustainable – from the time the car is purchased through its ownership and utilization phase and all the way to its resale..

The first link in the automotive value chain: Research & Development (R&D)

Procurement

Not only is Audi making its own processes more sustainable, it is also supporting business partners (page 65) in their sustainability efforts. In its corporate responsibility for the environment and society, Audi wishes to collaborate only with partners who adopt the same approach in terms of both their philosophies and actions. This not only includes environmental protection, but also employee rights and integrity. A mandatory sustainability rating records and governs just how well suppliers are able to implement the guidelines.

The rigorous electrification of the vehicle fleet has caused an increased percentage of the CO₂ emissions created during the lifecycle of the car to arise in the supply chain and during production. Thus, Audi is working with its suppliers to develop measures aimed at reducing carbon emissions. The Audi CO₂ program focuses on the production of materials that require a particularly high level of energy – namely aluminum and steel as well as battery components.

Respecting and protecting human rights is of the utmost priority for Audi at all times – especially throughout the supply chains. In line with the requirements of a risk-based approach, Audi concentrates its measures on the supply chains that are associated with particularly high risks for negative impacts according to analyses. Among the significant challenges facing electric mobility is the sustainable extraction of the required raw materials.

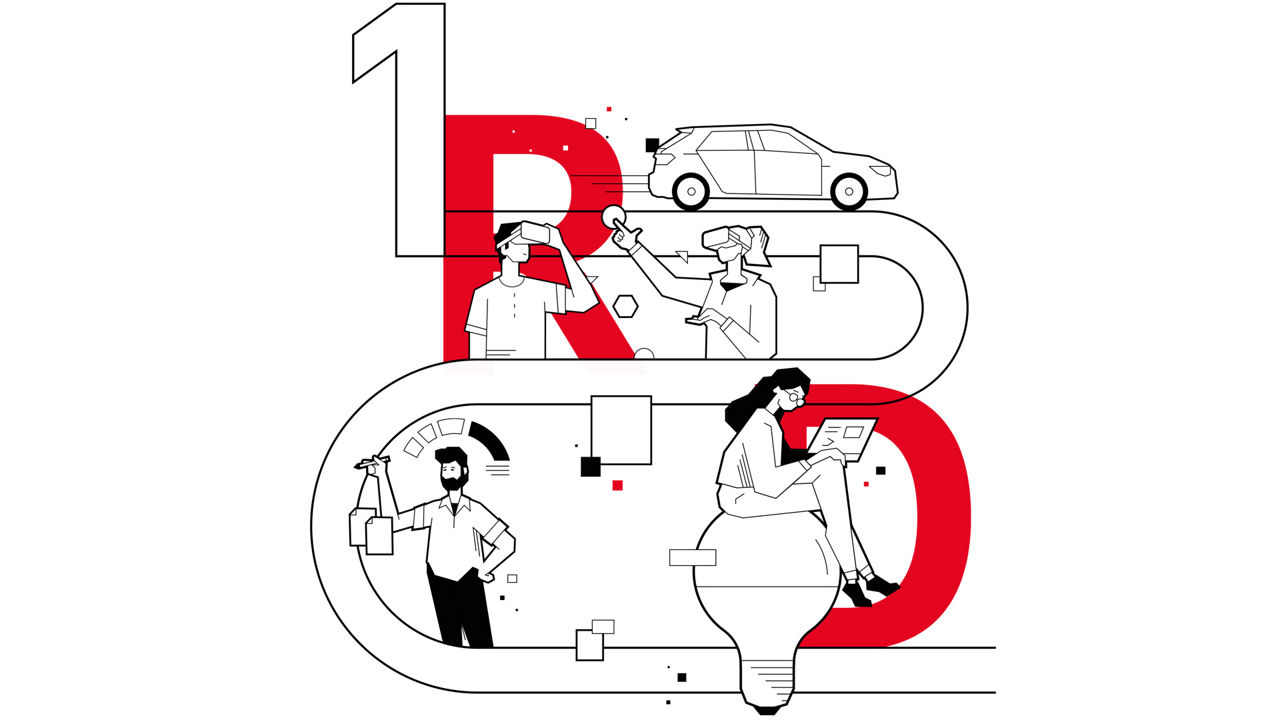

The second link in the automotive value chain is procurement (P), followed by production (P) as the third link.

Production

For decades now, Audi has been increasing the “fitness” of its production through intelligent, digitally connected high-tech solutions. The basis of environmentally compatible production at Audi is the environmental and energy management systems that have been gradually introduced since 1995. They help when it comes to achieving “Mission:Zero“ – that is, production with the lowest possible impact on the environment.

All Audi sites are pursuing ambitious goals and gradually reducing environmentally relevant values for the KPIs of CO₂ emissions, energy, fresh water, organic solvents (VOC) and waste. A functioning circular economy and reductions in energy consumption play a key role in this.

By 2025, the aim is to achieve net zero carbon emissions for all Audi plants. Since 2018, the plant in Brussels has served as role model – as the world’s first certified carbon-neutral large-scale production plant in the premium segment.

Marketing

In the future, Audi will invest 50 percent of its marketing budget in topics pertaining to electric mobility. The company plans to make new forms of propulsion even more emotionally tangible for its customers, dismantle possible reservations and ignite enthusiasm. The company’s podcast “The future is electric” is one successful example. The second season is currently on the air and was honored with the World Media Award in the “Automotive” category in 2019.

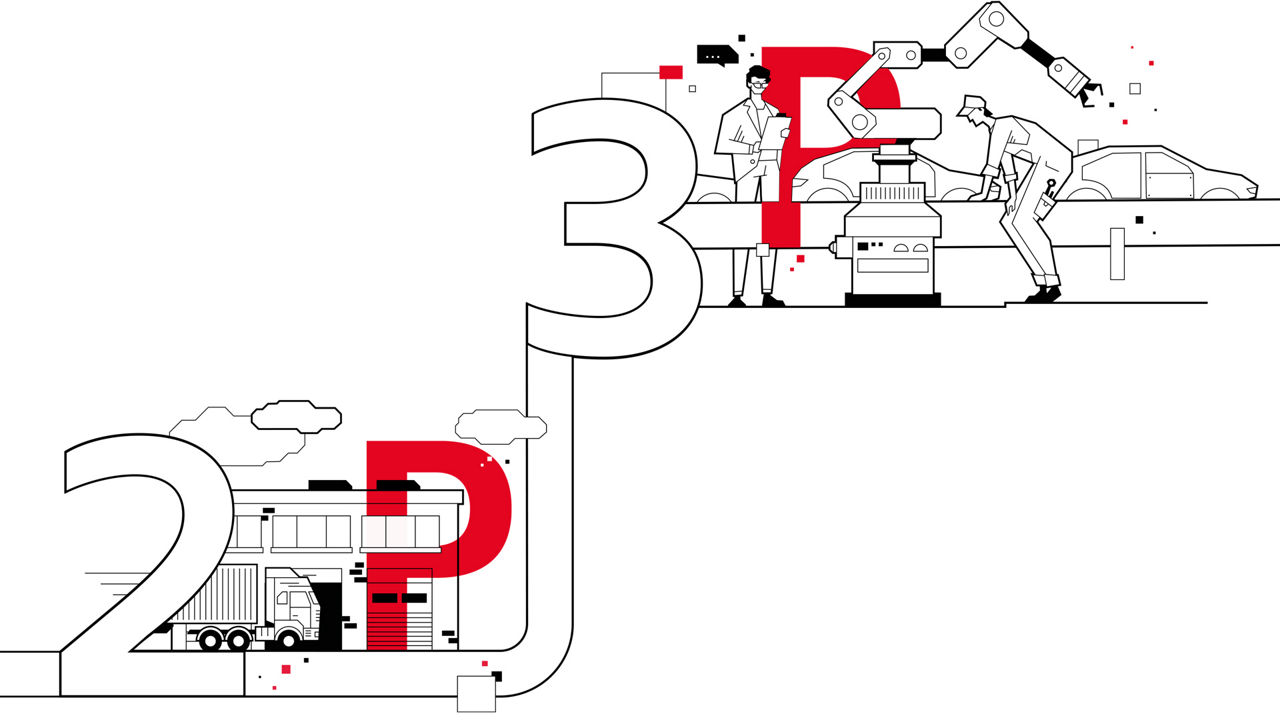

The fourth link in the automotive value chain is marketing (M). The fifth link in the chain is aftersales (A).

The fourth link in the automotive value chain is marketing (M). The fifth link in the chain is aftersales (A).

But it is not just digital channels where Audi is leading the way; the company also has tangible sustainable concepts for the future of sales: Ever since the fall of 2019, the new Audi Brand Experience Center at Munich Airport has served as a way for the company to demonstrate that economy and ecology are not conflicting concepts. The structure showcases the most modern form of energy and building technology, and has a multiplier effect – for example as an international training center or event venue.

After sales

The advent of electric mobility will pose new challenges for both dealers and workshops. In addition to oil changes and spark plugs, mechatronics technicians must now also be able to handle issues such as high-voltage technology. Audi is committed to supporting its service partners as well as possible throughout this transformation toward electric mobility, by offering innovative training concepts, for example.

Thanks to virtual reality training sessions, employees can become acquainted with technologies such as high-voltage batteries in a realistic and safe manner. During process training sessions, they learn step by step when it is time to replace a switching unit or battery module. The advantages of providing such virtual reality training sessions are clear: Audi can offer them on a global scale, thus ensuring that its electric vehicles are efficient, fast and enjoy premium market rollouts, with technicians who are already optimally prepared for the new model as soon as it is launched on the market.

Recycling

Audi not only focuses on conserving resources when designing and building its vehicles, the brand also promotes recycling and reusing – in keeping with the concept of the circular economy (page 62). This is why Audi has teamed up with (external) partners to create a comprehensive return network. In addition, materials used – such as plastics – are labeled and are thus easily recognizable.

Audi generally constructs its models so that they can be dismantled quickly and simply. When a vehicle is returned to an official Audi collection facility, it is drained and disassembled. Together with other manufacturers, Audi has developed the database IDIS (International Dismantling Information System) to optimize the overall process of dismantling. IDIS contains type-specific information for professional and environmentally-friendly handling, starting with information about draining automotive fluids, the neutralization of airbags and seat belt tensioners and all the way to the dismantling of components containing particularly hazardous substances, such as batteries. Containers for liquids, radiators or oil pans are constructed in such a way that they can be emptied in an uncomplicated and residue-free way. Furthermore, factors such as avoiding the long-term filling of oils and fats, as well as maintenance intervals geared toward driving modes and vehicle operating conditions, also reduce the amount of waste in workshops.

Used components and assembly groups such as engines, transmissions, axles, starters, electronic parts and many other components are then refurbished. This protects the environment, while offering customers the cost-saving alternative of exchanging a component for a recycled spare part.

The sixth link in the value chain bears the abbreviation "R", which stands for recycling.

The scientific history of the value chain

The value chain depicts production levels as an organized sequence of activities, which in turn create value, use resources and are linked to each other through processes. The concept was first introduced by the American economist Michael E. Porter in 1985. According to Porter, the value chain represents a collection of activities that are performed to design, produce, market, deliver and support a product.

“

The value chain represents a collection of activities that are performed to design, produce, market, deliver and support a product.”

Michael E. Porter, American economist

Moreover, it reveals the path a product or a service will follow throughout the transformation process. In the process, various tasks for rendering service are described, from development, procurement and production to sales and after-sales services. In practice, the value chain serves as a means of analyzing corporate activities and represents a complex methodological instrument.

.jpg)